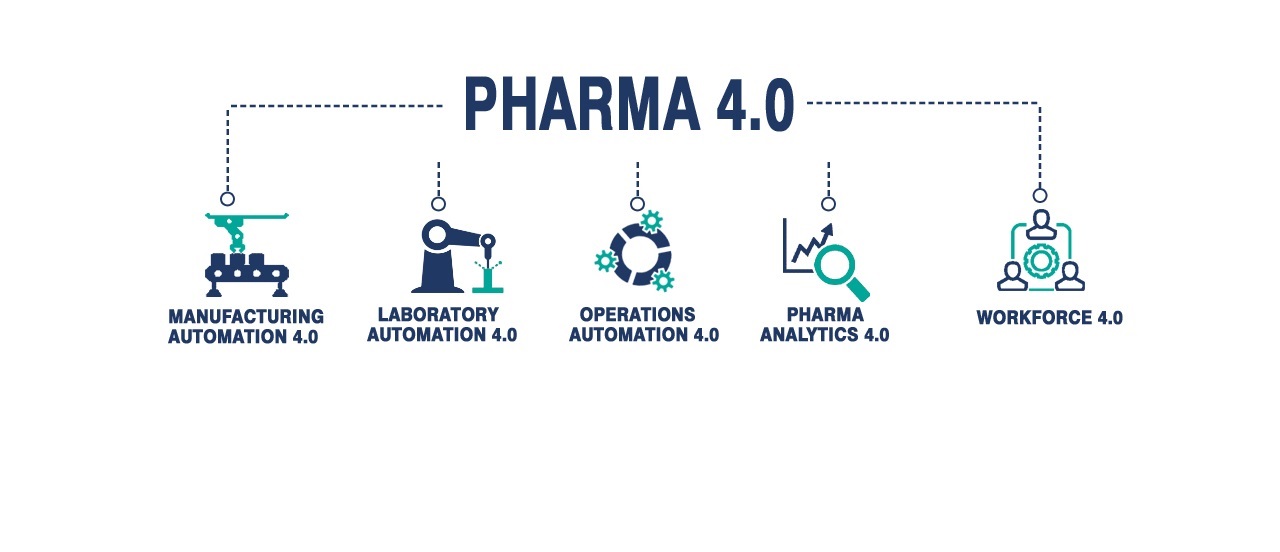

PHARMA 4.0

Pharma 4.0 envisions efficient, robust, and flexible manufacturing operations integrated with all parts of the manufacturing process as well as with quality and business functions. "Vertical Integration" of the manufacturing floor up to Manufacturing execution, ERP systems and Laboratory system (LIMS) - allows real time, data driven decisions. “Horizontal integration” of laboratory systems with Manufacturing process, equipment and facility systems allows feedforward and backward controls.

The availability of data from across the product lifecycle allows data driven process controls and predictive product quality that increases process robustness and improves quality.

Manufacturing Process Automation

Manufacturing Process automation is an aggregation of critical data elements from the Business Applications, Manufacturing and Quality processes.

Laboratory Process Automation

Laboratory Process Automation provides a structured platform for the entire laboratory operation with an institutionalized process and instructions for each test to be performed.

Contemporary Automation in Life Science (RPA, ML and AI)

Adaptive technologies such as introduction of Robotic process for handling routine and repetitive processes in quick time for disposition as well as the rigor in data management.

Workforce 4.0

Workforce 4.0 aims to develop the Skilled workforce to adopt the Pharma 4.0 expectations. New technologies are deployed in factories each day

Analytics 4.0

The future of Lifescience industry lies in overcoming barriers to innovation through extensive use of data analytics.

Manufacturing Process Automation

Manufacturing Process automation is an aggregation of critical data elements from the Business Applications, Manufacturing and Quality processes, Equipment’s and Instruments and the workforce into a single suite to execute Manufacturing in a paperless environment. This suite of solution is fully instruction led with control strategies built at every critical control point’s including integration of data from ERP systems, Planning application, Quality and Laboratory application, Training, Access control and attendance system to ensure all prerequisites are well integrated by design and comply with documentation quality which mirror the product quality.

The solution meets CFR guidelines in capturing data elements that are critical to regulatory inspections and generates a digital Batch Manufacturing and Batch Packing records, including exception reporting’s, alarms and escalations, trigger of quality events.

Principle Drivers of Adopting Manufacturing Process Automation in Lifescience Industry

Improved scheduling & resource utilization

Improved material tracking

Enforced sequence of operations

Shorter production cycles

Enhancing decision support

Reduced errors in production record

Assured Data Integrity

Realize paperless manufacturing

Review by Exception

Laboratory Process Automation

Laboratory Process Automation provides a structured platform for the entire laboratory operation with an institutionalized process and instructions for each and every test to be performed from Raw material – In-process Material – Finish Products. Laboratory managers can be confident that analysts are following testing procedures each and every time, while they are processing samples as quickly and efficiently as possible.

Automation of routine tasks reduces the workload for analysts and reduces the possibility of errors.

Integration with other informatics systems ensures that SOP requirements are rigorously followed each and every time.

Electronic worksheets can be quickly retrieved when needed for investigations, audits or to demonstrate adherence to regulatory compliance requirements.

Leverage Existing Processes

QA/QC personnel in the laboratory invest considerable time, expertise and knowledge in the development of the paper documents they use. Worksheets, bench forms, log books and SOPs represent processes and workflows that have been developed and refined over the course of time. Contemporary Technology leverages that investment by transferring existing paper documents directly into an electronic System where they become the interface that the analyst works with during test execution. Laboratories aren’t forced to change their processes in order to conform to the software. Training requirements are reduced and system acceptance is increased as analysts and technicians are able to work with a familiar and comfortable interface.

Real-Time Integration Delivers Advanced Procedural Control and Automation

Real time sharing of information that is critical to test execution. Having access to that information, at the time of analysis and at the bench level, enables to provide step-by-step control over the execution of procedures and to automate many of the manual activities that are the source of errors in paper-based systems.

Eliminate paper, Automate Processes and Control Procedural Execution

Eliminating the need to write on paper and transcript to a laboratory system is fraught with inherent transcription errors which are completely eliminated with instrument integration for data acquisition. This facilitates the analyst to concentrate on SOP requirements and test procedures rather than on data management.

Contemporary Automation in Life science (RPA, ML and AI)

Adaptive technologies such as introduction of Robotic process for handling routine and repetitive processes in quick time for disposition as well as the rigor in data management, use of Machine learning for transcribing master data, specifications, test procedures from manual records into a laboratory system provides the added advantage of improved data accuracy, zero error and reduced cycle time. Robotic Process Automation, together with ML and AI, enables the Lifescience industry to improve data accuracy, high level of data integrity while eliminating tedious tasks, thus becoming a key enabler in the growth of the Business.

Synthesis has pioneered these technology enablers and work with Lifescience organizations in the key areas enlisted below.

Address compliance and regulatory requirements

With a significant reduction in the possibility of human errors, RPA/ ML can assist the Lifescience industry to meet stringent standards and complex regulations.

Meet patient Safety expectations

With high-quality medicines / Medical Devices and compliance with regulations, the Lifescience Organizations can meet the patient’s Safety expectations.

Reduce Cost of Quality

RPA can help companies to reduce the cost of quality in the areas of Quality documentation, Management of production data, Laboratory Master data, etc.,

Reduced TTM (Time to Market)

contemporary technologies improves Performance by completing all repetitive tasks rapidly and also has a vital role in maintaining the Master records (MBMR, MBPR, MFR, MPR,Specifications, STP's, etc.,) and gathering real-time data.

Flawless data processing and reduction in report processing time can help the Life science organizations to come up with improved performance and high productivity. The additional processes can also be managed with ease by integrating RPA/ML/AI engines.

Workforce 4.0

Workforce 4.0 aims to develop the Skilled workforce to adopt the Pharma 4.0 expectations. New technologies–from wearable sensors to IIoT integration to advanced data analytics–are deployed in factories each day, and workers are expected to adapt, quickly. Experts expect this trajectory to continue. “the number of physically demanding or routine jobs decrease[s]… the number of jobs requiring flexible responses, problem-solving, and customization will increase. This means that learning and mastering new tools and technologies is now part of a manufacturing Executives basic job description.

The same technologies responsible for the decreasing complexity of manufacturing are improving job training. Augmented reality, manufacturing apps, and IoT connectivity are each making training programs more customizable and effective. These technologies are reducing onboarding times, simplifying reskilling, and closing the skills gap.

Pharma 4.0 way of Training Manufacturing & Laboratory Operators

As Manufacturing operations and regulatory expectation become more and more stringent, adaptive technologies are simplifying it. One of the most important use-cases of Pharma 4.0 technology has been employee training.

In contrast to training programs which are traditionally class room oriented and require resources to be diverted from production area, Pharma 4.0 training services are revolutionizing training. Employees self-guide their way through new processes, new method of learning on the job there by protecting precious time of the resources. Data on trainee progress in real time, allowing for continuous improvement and offer media-rich instructions customizable for every new task.

Classic examples revolve around tailored modules with images, video, audio, and feedback integrated into the process. IIoT connected devices (cameras, scales, barcode scanners) let workers check their work as they learn. Real-time data empowers supervisors with customized, data-driven feedback for their employees, allowing organizations to implement a “deep practice” approach and making the entire learning process more efficient. Manufacturing Apps let engineers design customized training applications for their specific outputs. Wearable sensors track employee movements, helping them learn faster and find new places for process optimization. Augmented reality (AR) glasses and displays immerse workers in their training.

Analytics 4.0

The future of Lifescience industry lies in overcoming barriers to innovation through extensive use of data analytics. We need to move past the challenge of unstructured data sets and data in multiple systems to a more integrated data framework to drive Retrospective, Prospective and Predictive analytics. In organizations where there are extensive plans for digital transformation initiatives, big momentum for implementation of Robotics and Artificial Intelligence platforms “Data analytics will be a game changer”, which need to be embraced - and fast.

The earlier Organizations realize that No single system can leverage the Business Outcome and Interoperable Analytics framework is the key to success, Business strategies and decision making becomes data driven function. Our enabling technologies as a part of Pharma 4.0, provides visibility across the hierarchy with “Real-time Analytics” and “Predictive Analytics” to gain insights into all the operational areas of “S&OP”, “Manufacturing & Quality” and “R&D Function” to attain greater efficiency, effectiveness in the organizational functioning.